Overview

The internal environment control system is a highly intelligent automatic control system which integrates mechanical, electrical and computer control specially developed by Megaphoton for the internal environment control of the greenhouse.

Its electronic control system is divided into three parts: the main circuit of the power distribution room, the control system circuit and the partial circuit of the fill light.

The core of the electronic control system is the control part, which is divided into sensor unit, control unit, execution unit and bus system.

By controlling the fans, fertilizer applicators, curtains, skylights, wet curtains, fill lights and other parts in the greenhouse, the entire environmental system in the greenhouse is controlled.

Technical Features

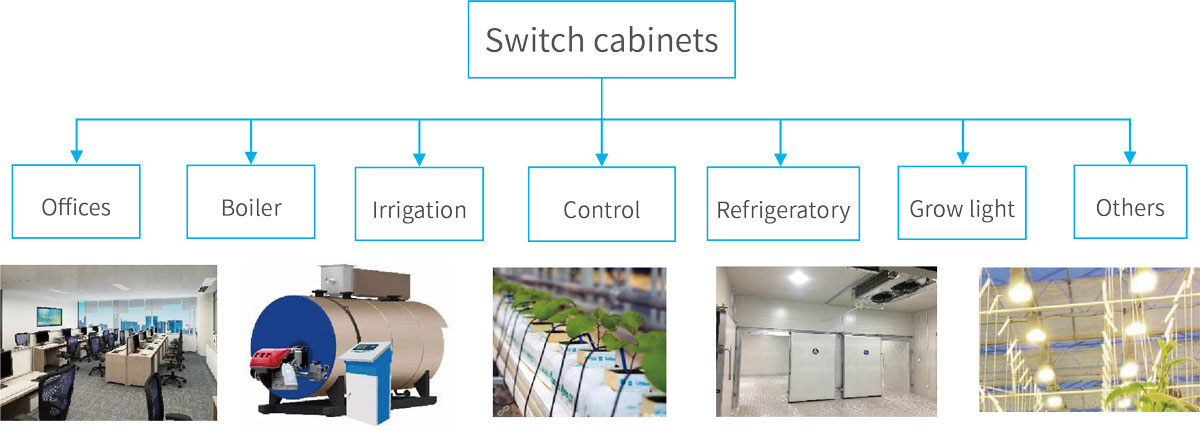

Megaphoton will design different switch cabinets according to different user needs, and tailor different electronic control systems for the different internal environment control systems of each greenhouse.

The switchgear and control cabinet shall be firmly installed, reasonably arranged, neatly arranged and beautiful, with neat wiring and complete signs and numbers. Components with the same structure can be interchanged, and the equipment is highly maintainable.

Each distribution box has enough maintenance space for easy maintenance and repair.

The power distribution cabinet can be monitored and controlled in real time by the computer. Data such as daily electricity consumption of each part of the climate system can be generated on the computer to facilitate the management of system electricity consumption.

Main circuit of power distribution room

According to different switchgear designs, the shape and structure of the switchgear in the power distribution room are different, but they all have the following characteristics:

1. Adopt bottom-in and bottom-out wiring method, front door, convenient wiring and maintenance;

2. It is made of high-quality cold-rolled sheet with a thickness of not less than 2MM, and the surface is plastic-sprayed;

3. Equipped with a complete and reliable grounding protection circuit to ensure the safety of equipment and operation and maintenance personnel;

4. There are different numbers of cooling slots at both ends of the cabinet.

Schematic diagram of the main circuit of the power distribution room

粤公网安备 44040402000132号

Terms of service and privacy

粤公网安备 44040402000132号

Terms of service and privacy